Some recommendations, considerations and potential issues to keep in mind while working with the operation link path.

|

|

|

|

|

|

Link path rework.

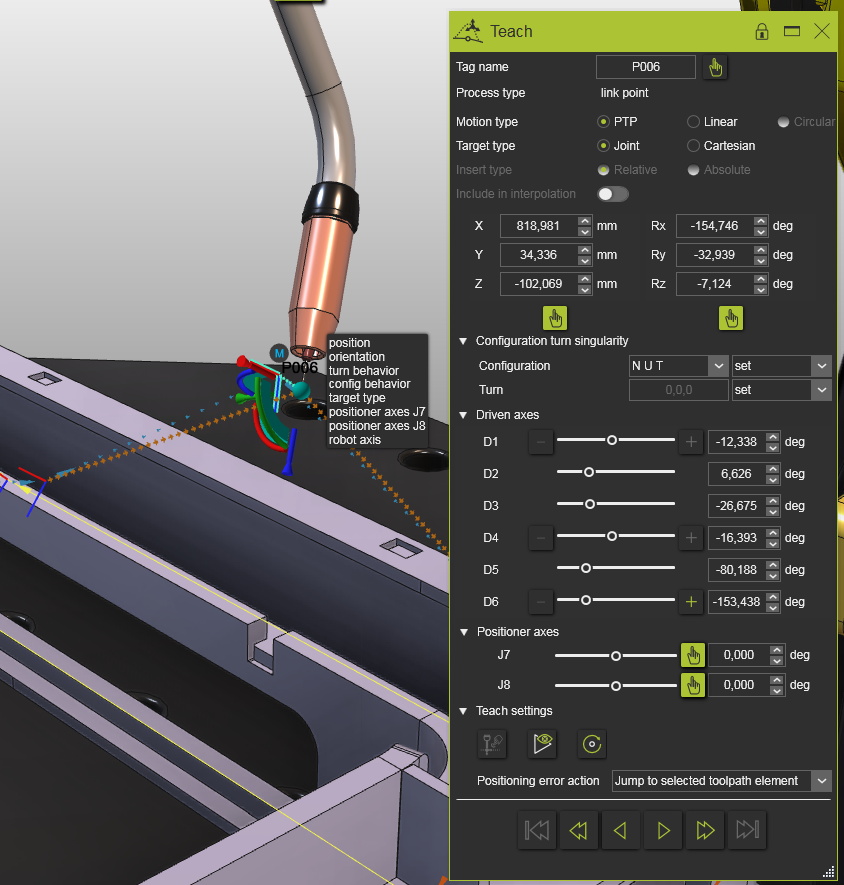

Link path elements created by ALG can be modified manually. Except for the motion types, all teach data can be modified.

|

|

|

|

Removing an operation link path generated with the ALG command.

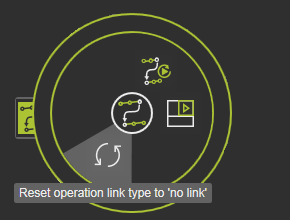

Remove a single link path by right clicking the link path in the flowchart and select the Reset command.

Remove all link paths in the program by changing the link type to No link.

|

|

|

|

When to re-run the link path generation?

ALG should be run again if something has been changed in the program that affects the creation of the link paths.

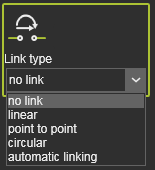

In such cases, a link path that has already been created is marked as outdated in the Toolpath dashboard. The icon for the optimization status has been grayed out.

Run ALG again for the entire program or just for the outdated link path operation to get an updated, safe link path again.

|

|

|

|

|

|

|

When the command is not available

•The Premium license configuration to which ALG belongs, is not available.

•ALG has not yet been released for the technology used.

•The specific machine or robot kinematics is not supported. |

|

|

|

When the command fails to generate a link path

•The retract position of the first operation and the approach position of the second operation might be in collision. They cannot be modified by the generator.

•No collision-free path can be found based on the given ALG parametrical setup (would require more time / iterations or lower collision tolerance …).

•There is no solution at all.

Possible solutions or workarounds:

•Make the link path’s start- and end-point collision-free and reachable before running the ALG command.

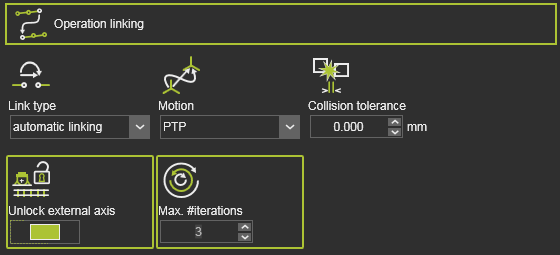

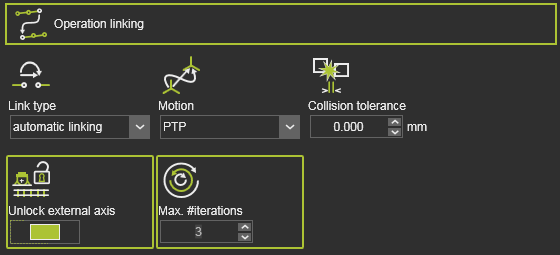

•Increase the expert attribute values in the Operation linking container.

oA higher number of ALG iterations creates a better link path.

oTurn the option Unlock external axis to ON to make use of an extended external axis value range.

|

|

|

|

When there still are collisions during simulation after a successful generation of the link path..

•The motion along the link path is too close to the geometry.

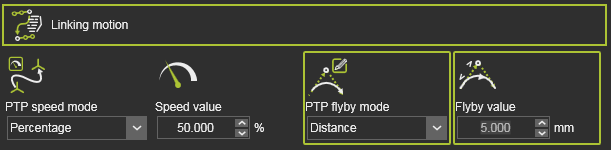

•The generation of the link path does not consider any flyby motion when checking for collision. Simulated motion, with flyby, can be slightly different compared to the motion data used in ALG where the exact toolpath position coordinates are used and cause collisions within the flyby zones.

Possible solutions:

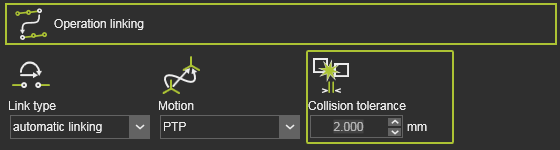

•Set or increase the Collision tolerance value. Make sure not to choose a value that is too high, as this can prevent finding a solution if there are only collisions as a result.

•Verify or modify the flyby definition.

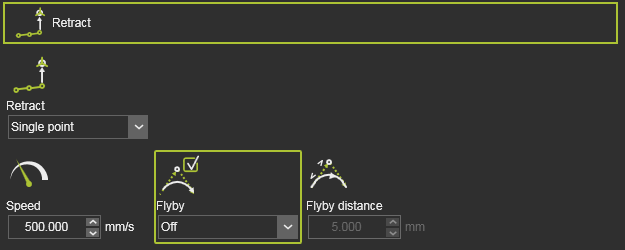

oSet the flyby to OFF in any Retract section.

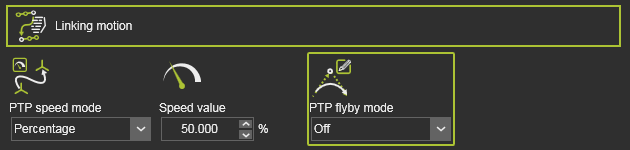

oSet the flyby to OFF for the link path, if not done already.

oWhen flyby is needed in retract and / or on link paths, set the Flyby distance value to the required minimum. Sometimes it is set unnecessarily high.

|

|

|

|

When the link path is too far away from the geometry (workpiece), improve the link path result by modifying the expert attributes.

•A higher number of ALG iterations creates better link paths which lie closer to the workpiece. A lower number runs the ALG faster.

•Unlock the external axis values. If unlocked the algorithm sometimes creates path positions more far away. However, if this option is turned OFF, the generator will not find a solution in some special cases.

|

|

|

|

When the computation is running longer than expected:

The main reason for this is the complexity of the workcell, and, related to it, the computational effort required for the collision detection while running the ALG is high.

Solutions / Workarounds:

Simplify the collision checking. Check whether some of the collision check relationships can be deactivated or whether collision groups can be simplified or removed completely.

|

|

|

|

|

|

|

Current functional limitations to consider when using the Automatic link path generation.

|

|

|

Available for the following technologies:

•Arc welding

•Laser welding

•Laser cutting |

|

|

|

Supported link path motion types:

•PTP

•LIN

Circular (CIR) or combined motion is not supported.

|

|

|

|

Automatic link path generation does not optimize operation approach and retract positions. Users must modify them manually to make them collision-free.

|

|

|

|

Because not all machine or robot kinematics are supported yet, the command might not be executable in all cases.

Supported kinematics:

•5x Machining: gantry-head, nutator (TTTRRhh)

•6x Robotics

oArticulated (RRRRRR)

oOffset wrist (RRRRoRR, RRRRRoR)

oAngulated wrist (RRRRRaR)

o6x portal kinematic (TTTRRR)

oPTP link paths only: Robots with more than 6 axis, including additional internal external axis e.g.7-axis robots (OTC, Fanuc, Kawasaki, KUKA)

Not supported:

•Machining

oTable kinematics (head-table and table-table)

•Robotics

oDouble angle wrist

oKinematics with dependencies between axes within forward kinematics, e.g.parallelogram between axis 2 and 3

oEdition 2 generic

oOther special kinematics |

|

|