|

|

|

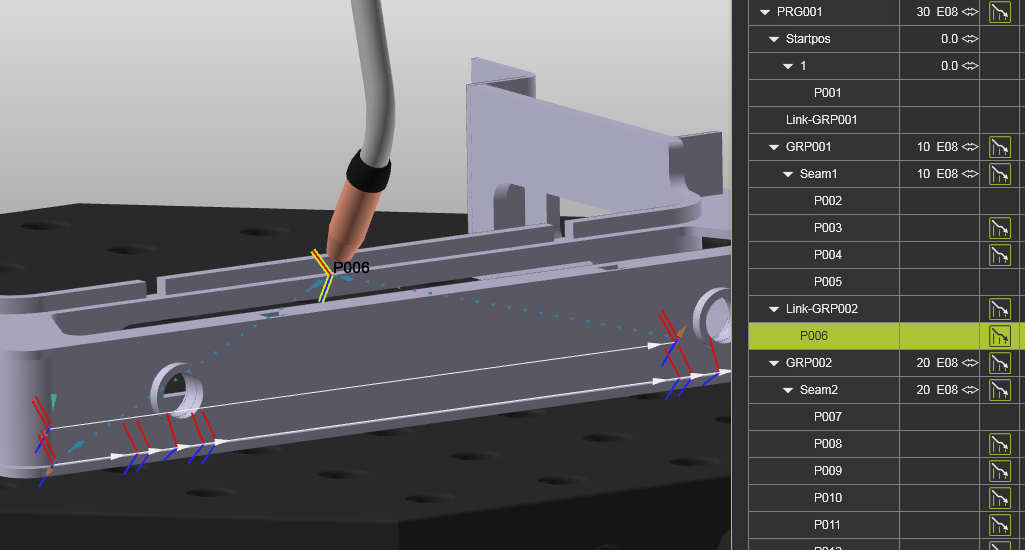

The Automatic link path generation (ALG) creates the paths between two sequential programmed operations. To ensure a proper solution, the end of the source operation and the start of the target operation must already be collision-free and reachable.

|

|

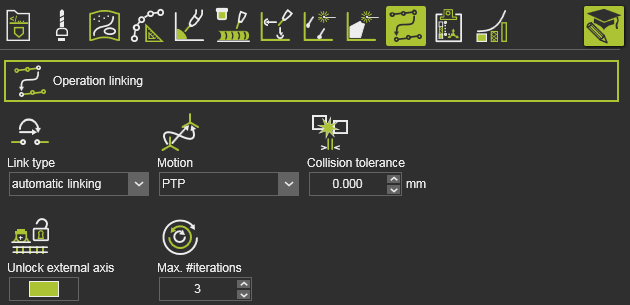

Before being able to run the automatic path generation, the link path attributes need to be set accordingly. This can be done in the Programming defaults, before programming the operations, or afterward in the Active program dashboard.

|

|

|

|

|

|

|

Link type

|

To enable the automatic generation, the type has to be set to automatic linking.

|

Motion

|

For robotic scenarios:

Use the default PTP link motion type in general use cases.

Linear motion (LIN) may fail if there are configuration changes or turn changes which cannot be solved without a PTP motion.

|

Collision tolerance

|

Path optimization does not consider flyby motion effects. Thus; collision still may occur during the flyby.

Set the collision tolerance to a higher value than in the simulation setting, to get a safer result. Optimization with increased collision tolerance will consider some safety distance.

Be aware to not define a lower tolerance than the value in the simulation settings.

|

|

|

|

|

|

Unlock external axis

|

Disable this option to run ALG a little faster and to create paths closer to an optimum. Note that this may lead to unsuccessful results in some rare cases.

|

Max. #iterations

|

Increase the value to create better link paths, decrease it for faster calculation.

|

|

|

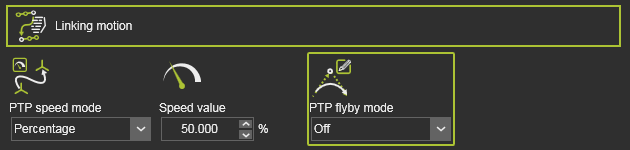

Then specify the link path motion attributes, depending on the selected link type (PTP or LIN).

|

|

|

|

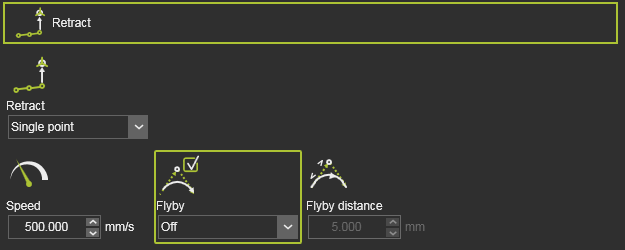

Watch for the approach and retract options of the operations between which the link path is going to be generated.

|

|

When cycle time optimization is not in focus, the first approach point and last retract point should be defined as flyby OFF motions.

|

|

The motion to the first approach (of the second operation) is specified by the link motion attributes itself. Take care to have the Flyby mode set to OFF here.

|

|

The flyby setting for the motion to the last retract point (of the first operation) is specified in the Retract attributes of that operation. Set it to Off to avoid any collision issues after ALG due to flyby effects that cannot be considered in the link path generation.

|

|

|

|

|

To ensure that the link path is going to be displayed in the 3D toolpath, verify that the corresponding toolpath display filter has been activated.

|

|

|

|

|

|

|

|

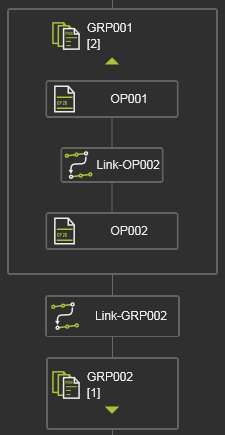

The link path can be executed at program, operation group and at operation level. And once it has been created also at its own entity in the flow chart or toolpath dashboard.

|

|

|

|

However, it is recommended to execute the generation (always) after that the process toolpath has been optimized, either automatically or manually.

|

|

The link path generation can be started in combination with the automatic process path optimization, as the second step of the autonomous programming command.

|

|

|

|

|

|

Partial simulation

|

|

Toolpath transformation

|

|

Lock the initial program

|

|

Autonomous programming

|

|

|

|

Or it can be started individually from the sub menu:

|

|

|

|

|

|

Automatic process path optimization

|

|

Automatic link path generation

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Partial simulation

|

|

Reset the operation link to None

|

|

Automatic link path generation

|

|

|

|

|

|

The new operation link path is computed and the result immediately is being displayed in the 3D view, in the flow chart in the Active program dashboard and in the Toolpath monitor dashboard.

|

|

|

|

|

Any change made to the attributes of the operation link require a recompute. This is not done automatically, thus needs to be triggered by restarting the command.

|

|

|

|

Once the link path has been generated, it can be reviewed in the simulation. Right click on a single link path operation in program flowchart to run the partial simulation on this link path only.

|

|

|

|

|

Autonomous programming

|

|

Besides running this autonomous programming functionality at the existing program, operation groups or individual operations, they can be executed also when programming a new operation.

|

|

In the Process geometry definition panel and in the Programming settings panel there is an option to define if the autonomous programming functionality has to be executed immediately after the operation has been computed.

|

|

|

|

|

|

|

|

|

|

No optimization

|

The operation is computed. No further autonomous optimization will be executed.

|

|

Full autonomous optimization

|

After the initial toolpath has been computed, all autonomous optimization methods will be run.

|

|

Automatic process path optimization

|

The in-process part of the operation, the toolpath, will be optimized.

|

|

Automatic link path generation

|

Optimize the motion, the link between operations to move collision free.

|

|

|