|

|

|

The initially programmed toolpath must be correctly defined so that it can be used as a reference for all modifications. Ideally, this initial toolpath should be optimal in terms of process quality.

|

|

Therefore, the initial toolpath and the corresponding creation attributes must ensure at least the following:

The normal direction must be correctly directed in relation to the workpiece surface for each operation. The normal direction must be correctly directed in relation to the workpiece surface for each operation.

The Tool alignment must match the TCP definitions used in the program. The Tool alignment must match the TCP definitions used in the program.

The Approach direction must be correctly defined for each operation. The Approach direction must be correctly defined for each operation.

All local offsets resp. process angles must be set to the target values, e.g.: All local offsets resp. process angles must be set to the target values, e.g.:

•For arc welding, the work, travel and tool angle.

Define, where required: Define, where required:

▪The process orientation

▪The tangent absolute

▪The overrun

▪For arc welding: the box welding |

|

Consider good programming to include:

|

|

Well defined robot and external axis starting position:

Program external axes explicitly at least at the very first TPE in program. Program external axes explicitly at least at the very first TPE in program.

Define PTP position at the very first point in each operation. Define PTP position at the very first point in each operation.

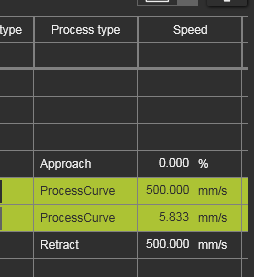

Define approach and retract points of the process type Approach and Retract. Do not use teach inserts on process points. Define approach and retract points of the process type Approach and Retract. Do not use teach inserts on process points.

|

|

Well defined speeds programmed at all toolpath elements:

No zero (0) speeds on process points. No zero (0) speeds on process points.

|

|

|

Optimization control

|

|

The most relevant attributes to define:

|

|

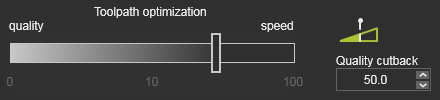

Quality cutback

|

|

|

|

To speed up the optimization process in general, the Quality cutback attribute comes in place. With this attribute a balance between finding the most optimal result and the fastest computation time is made. When using this attribute (values > 0), the iteration step of the methodology will no longer search for the optimal solution within that step, but will stop already when an iteration result meets the requirements, although that result might not be optimal. The sooner that decision can be made, the less computation time will be needed to come to a final result. Obviously because that final result might not be the global optimum, the result quality will be lower, i.e the resulting evaluation costs are higher than optimal.

|

|

Set a high value for faster calculations but lower quality result.

|

|

You may lower this value later on to get higher quality results, but at costs of longer calculation times.

|

|

Collision avoidance

|

|

|

|

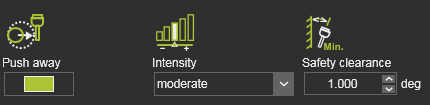

In the simulation settings is defined with what tolerance a possible collision is being analyzed. If the toolpath position leads to a collision, the optimization tends to choose the solution which is very close to collision, to minimize an increase in costs. This solution then still may be an unsafe situation or high risk because:

The path optimization does not consider flyby motion effects. The path optimization does not consider flyby motion effects.

Inaccuracy between the digital model and the real-world situation. Inaccuracy between the digital model and the real-world situation.

|

|

Optimization with use of the Push away attribute

|

|

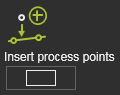

Insert process points

|

|

|

|

Automatic insertion of process points may improve the toolpath quality results and may lead to lower computation times. But deactivate if no additional points are to be inserted in case of collisions to be solved between the given toolpath elements.

|

|

|

Additional options to consider:

|

|

Use turn values

|

|

|

|

For robot axis, to consider the multiple turn against of the axis. This may leave unsolved unwind situations in linear or circular motions, where a robot cannot move along.

|

|

Deactivate if you don‘t want to consider multiple turn variants.

|

|

|

Variation space

|

|

Usually there is nothing to adjust here. A few things to keep in mind:

|

|

Normal rotation

|

|

|

|

The variation of the normal rotation might be de-activated, when the tool angle never should be modified. This will speed up optimization calculation but reduces the possibilities in modifying the toolpath positions in order to solve collisions or unreachable positions. It also might reduce the overall toolpath quality.

|

|

|

Maximum process angle deviation

|

|

|

|

The boundary condition Maximum process angle deviation by default is not editable. This is because its corresponding quality criteria has been switched ON for the toolpath evaluation. The optimization will then use that critical threshold value to find the optimal solution.

|

|

|

|

|

|

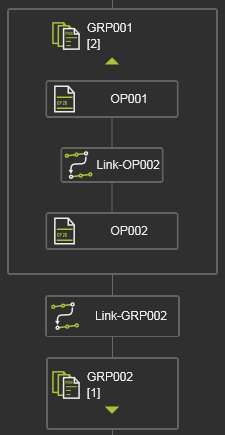

The process path optimization can be executed at program, operation group and at operation level.

|

|

|

|

The process path optimization can be started in combination with the automatic link path generation, as the first step of the autonomous programming command.

|

|

|

|

|

|

Partial simulation

|

|

Toolpath transformation

|

|

Lock the initial program

|

|

Autonomous programming

|

|

|

|

Or it can be started individually from the sub menu:

|

|

|

|

|

|

Automatic process path optimization

|

|

Automatic link path generation

|

|

|

|

|

|

|

|

|

|

|

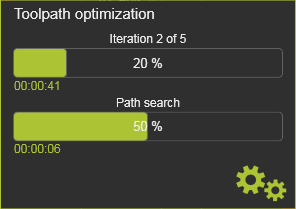

When the command is executed, a panel appears to indicate the progress of the optimization process.

|

|

|

|

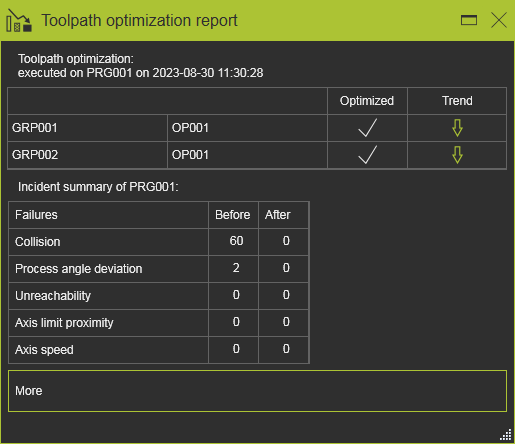

With the optimized toolpath a report window appears. In this report a summary is being displayed, as in the example below.

|

|

|

|

Hovering over the Trend arrow opens a small panel with the costs evaluation before and after the optimization steps.

|

|

|

|

|

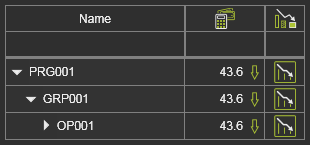

In the Toolpath monitor dashboard is shown on which parts of the whole program the automatic path optimization has been executed.

|

|

|

|

|

|

|

|

Autonomous programming

|

|

Besides running this autonomous programming functionality at the existing program, operation groups or individual operations, they can be executed also when programming a new operation.

|

|

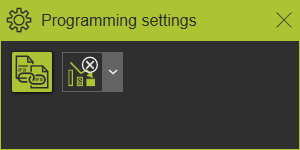

In the Process geometry definition panel and in the Programming settings panel there is an option to define if the autonomous programming functionality has to be executed immediately after the operation has been computed.

|

|

|

|

|

|

|

|

|

|

No optimization

|

The operation is computed. No further autonomous optimization will be executed.

|

|

Full autonomous optimization

|

After the initial toolpath has been computed, all autonomous optimization methods will be run.

|

|

Automatic process path optimization

|

The in-process part of the operation, the toolpath, will be optimized.

|

|

Automatic link path generation

|

Optimize the motion, the link between operations to move collision free.

|

|

|